Chen Hsong Showcases Revolutionary Moulding Technology at PLASTPOL 2023

As the final day of PLASTPOL 2023 is nearing its end, we at Chen Hsong are thrilled to look back on a highly successful showcase

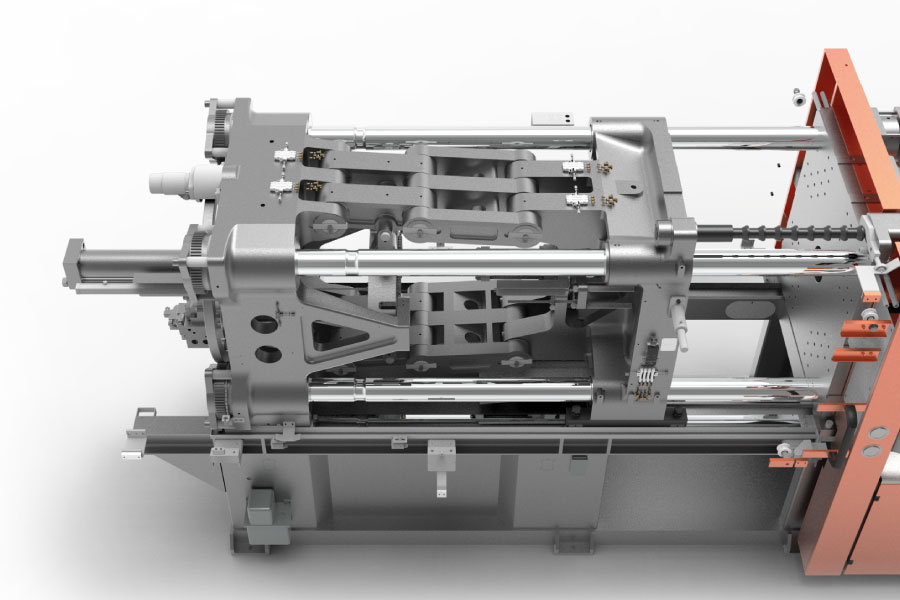

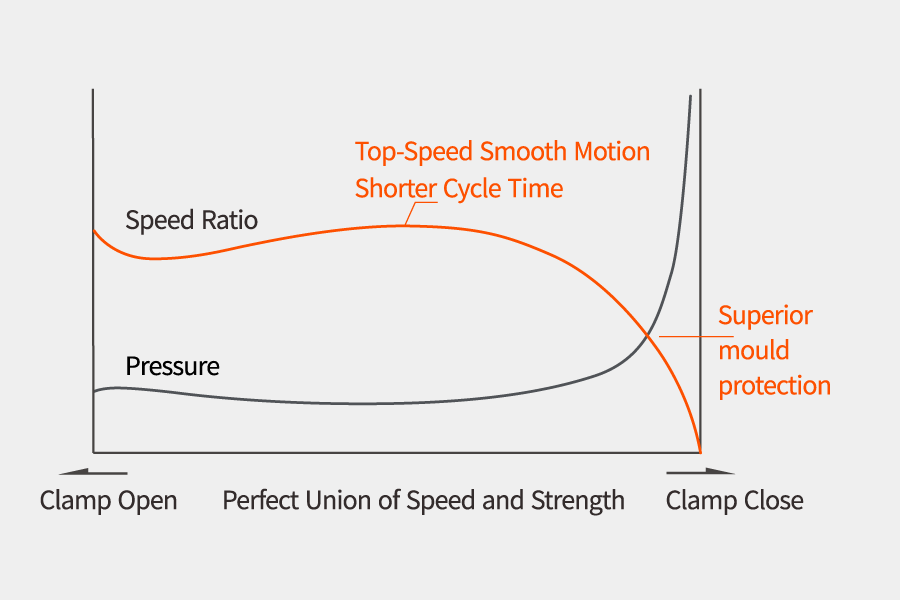

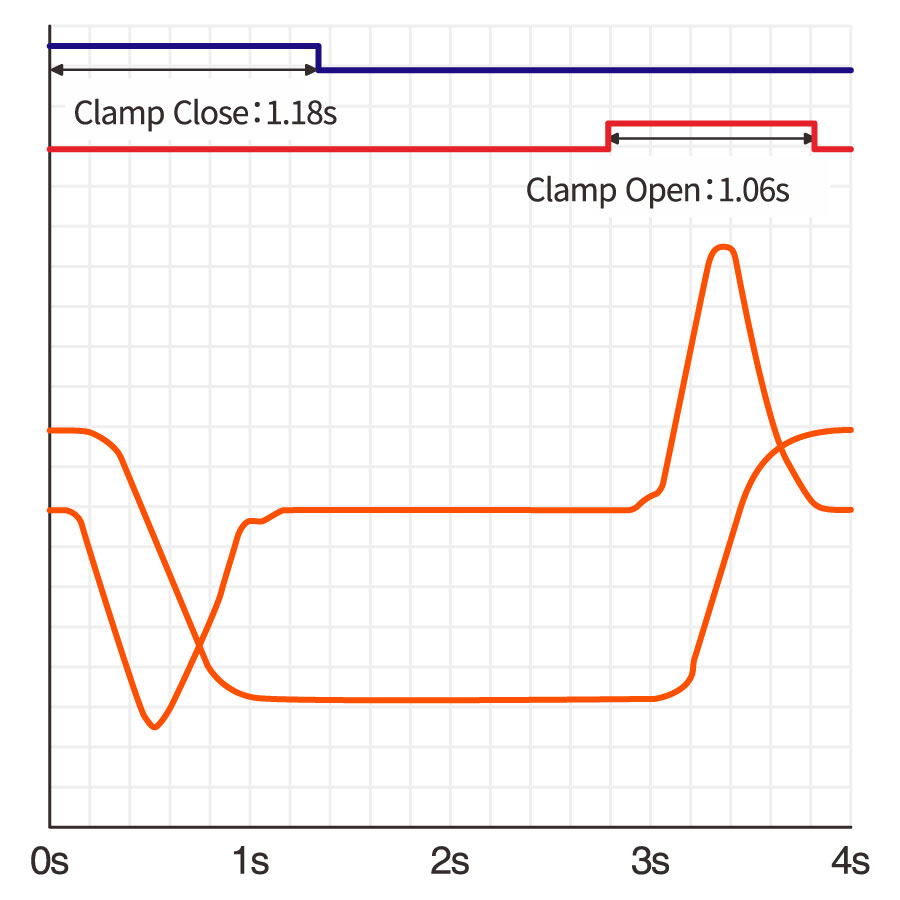

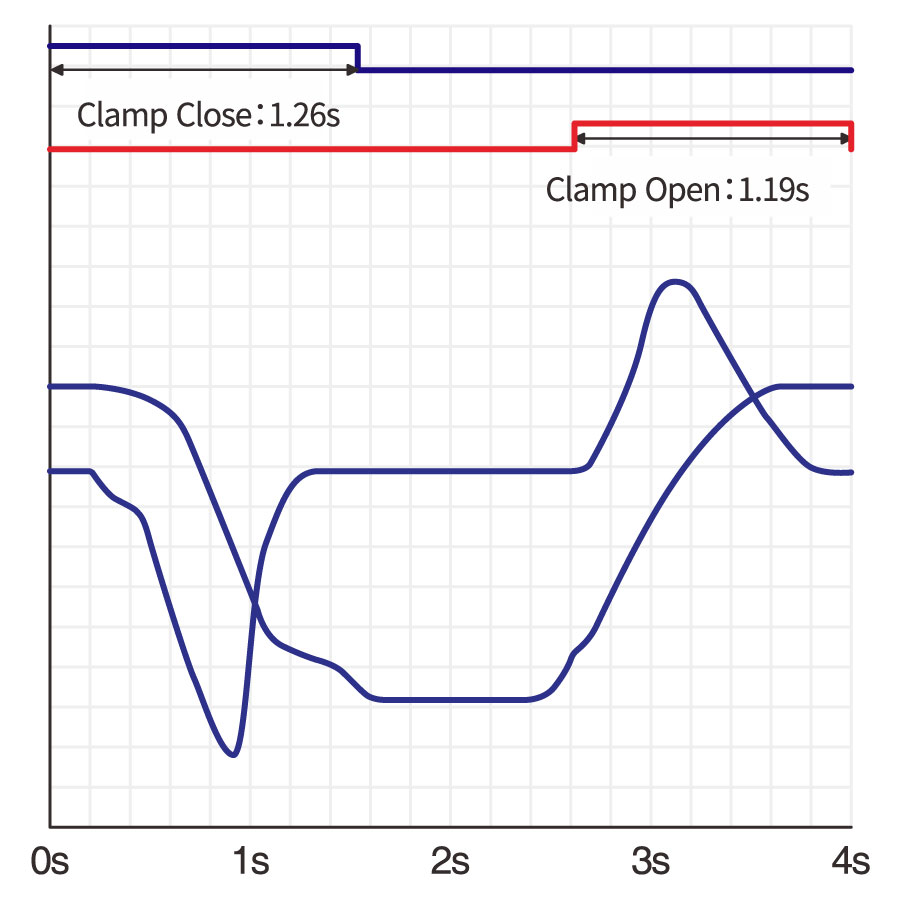

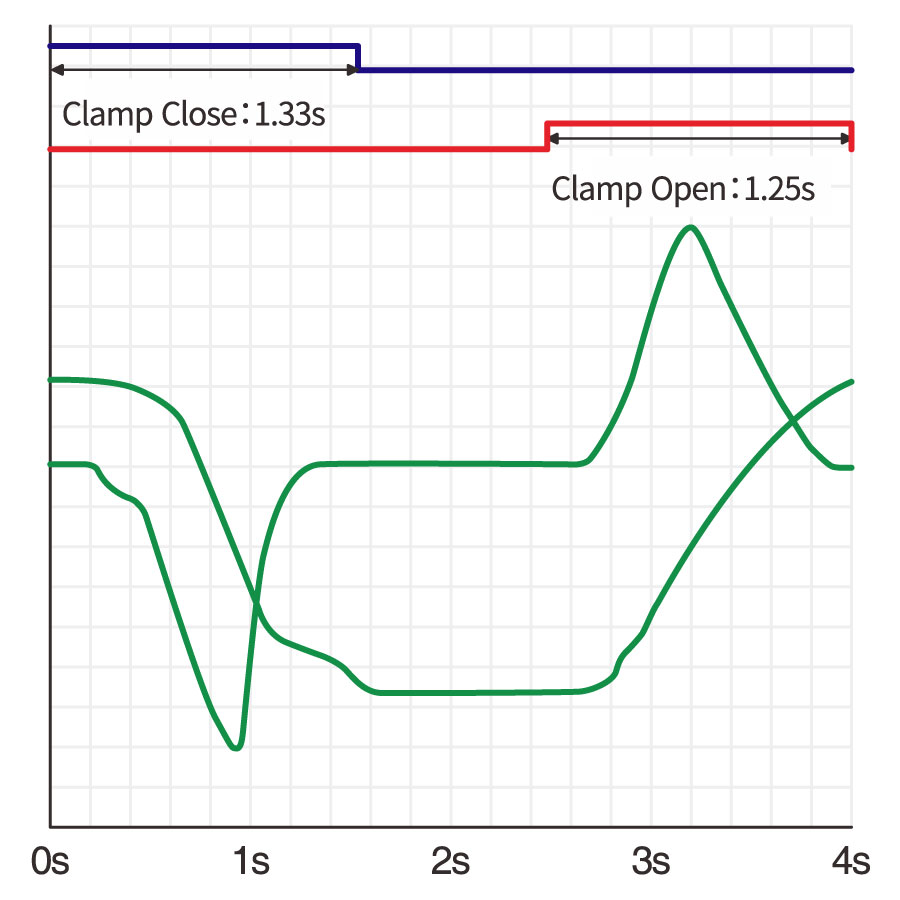

Professional Japanese mechanical experts took the latest and newest in toggle design and hand-fitted a motion-control profile based on large amounts of software simulation and real-life verification.

This combination largely avoids unnecessary friction and shocks among mechanical components, distributes tension uniformly to all tie-bars, and ensures a high degree of parallelism, in order to prevent flashes on parts and reduce toggle wear.

The result is a toggle system that moves snappily, silky-smooth and with no vibrations, improving power efficiency and usage life while protecting against mould damages and unscheduled downtime.

Finely tuned by leading Japanese hydraulic experts, and enhanced via proprietary fluid-dynamics simulation software, the entire hydraulic circuit is optimised to a high degree of perfection.

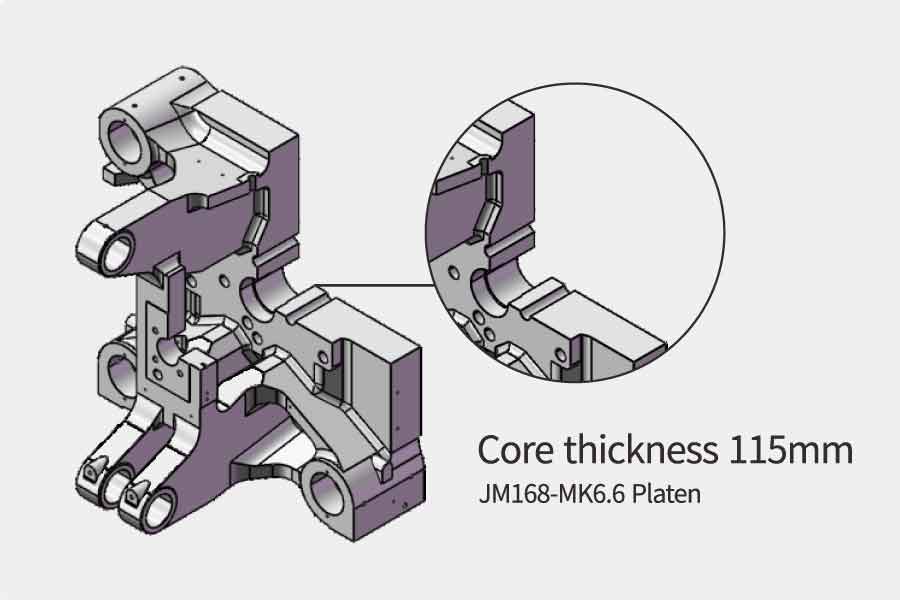

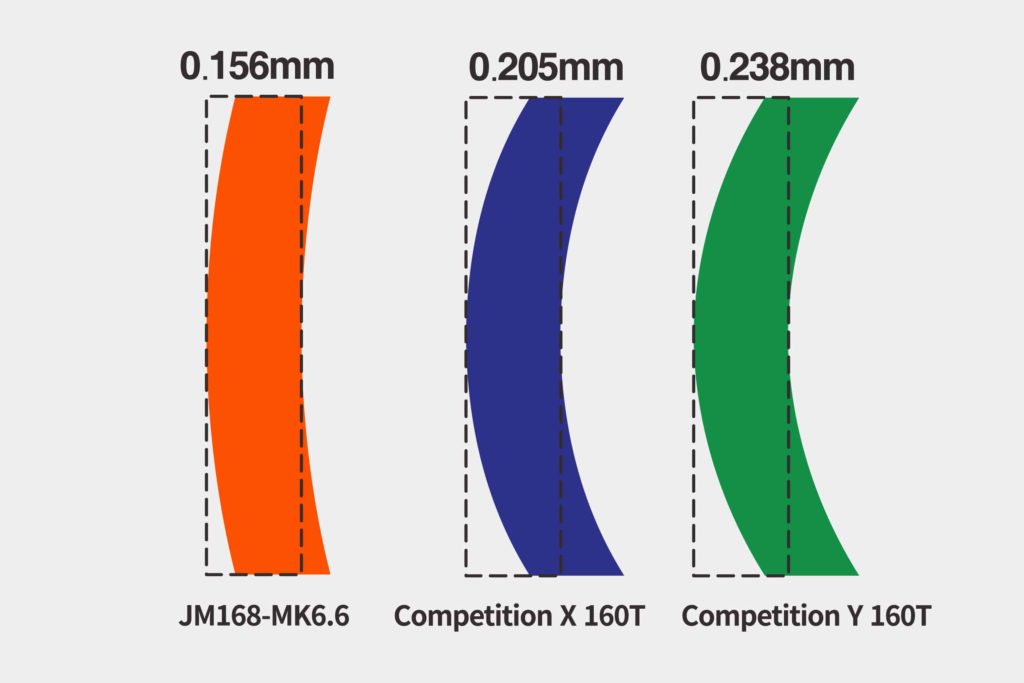

The centre of both platens is thickened to achieve lower deformation, and thus more uniform clamping force on the mould than most competitive offerings.

LED lighting part

Shot Weight : 121g

Cavities: 8

Resin : PC

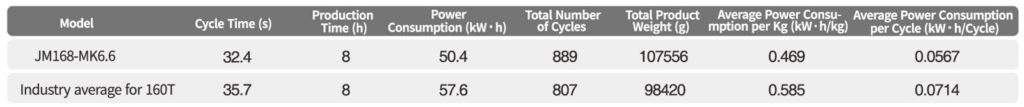

Cycle Time : 32.4s

Mould

Weight : 350kg

Dimensions : 400mmx400mmx300cmm

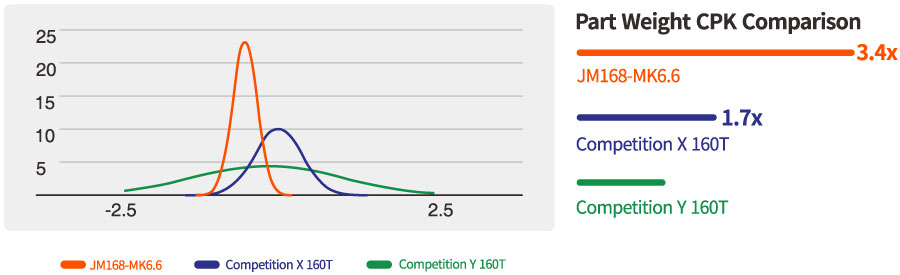

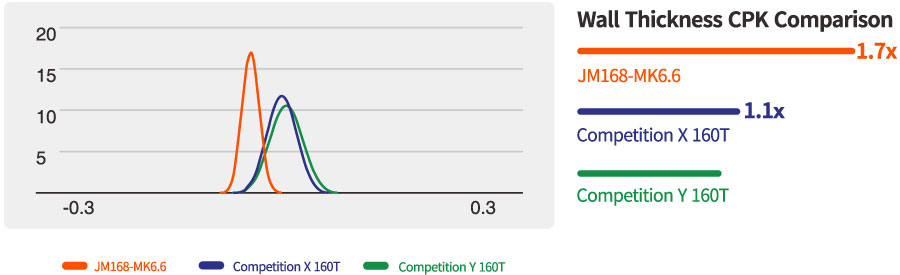

CPK (Process Capability Index)- higher is better, indicating higher stability and quality.

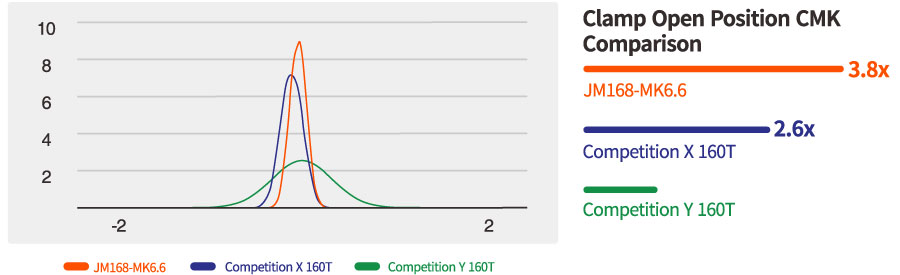

CMK (Machine Capability Index) – higher is better, indicating higher repeatability and better control

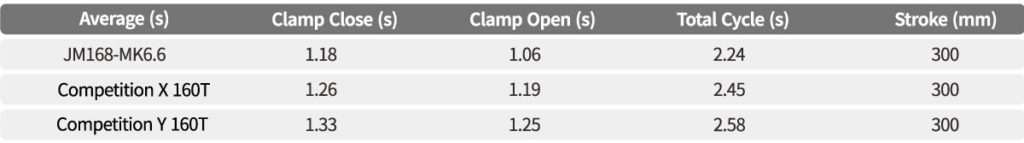

Faster is always better

(889-807)x3x21/24x30x11x10=

Efficiency is the name of the game

(0.0714-0.0567) x8,000, 000×0.25=

| Machine Model | Clamping Force (Max) | Opening Stroke | Space Between Tie Bars (HxV) | Max. Mould Thickness | Min. Mould Thickness | Maximum Daylight | Ejector Force | Ejector Stroke | Center Ring Diameter |

|---|---|---|---|---|---|---|---|---|---|

| Unit | t | mm | mm | mm | mm | mm | t | mm | mm |

| JM88-MK6 | 88 | 330 | 360 x 360 | 380 | 130 | 720 | 2.8 | 100 | 125 |

| JM128-MK6 | 128 | 370 | 410 x 410 | 450 | 145 | 830 | 4.2 | 120 | 125 |

| JM168-MK6 | 168 | 420 | 460 x 460 | 520 | 160 | 970 | 4.2 | 140 | 125 |

| JM208-MK6 | 208 | 490 | 530 x 530 | 550 | 180 | 1060 | 6.7 | 150 | 160 |

| JM258-MK6 | 268 | 530 | 580 x 580 | 610 | 195 | 1140 | 7.7 | 170 | 160 |

| JM328-MK6 | 328 | 600 | 660 x 660 | 660 | 220 | 1340 | 7.7 | 170 | 160 |

| JM398-MK6 | 408 | 670 | 730 x 730 | 730 | 250 | 1450 | 11.1 | 220 | 160 |

| JM468-MK6 | 488 | 770 | 810 x 810 | 810 | 275 | 1670 | 11.1 | 220 | 200 |

| JM568-MK6 | 568 | 835 | 855 x 855 | 850 | 330 | 1750 | 16.6 | 250 | 200 |

| JM668-MK6 | 658 | 920 | 900 x 900 | 920 | 350 | 1840 | 18.2 | 265 | 200 |

| Model ID | Swept Volume | Swept Volume | Swept Volume | Injection Weight (PS) | Injection Weight (PS) | Injection Weight (PS) | Screw Diameter | Screw Diameter | Screw Diameter | Screw L/D Ratio | Screw L/D Ratio | Screw L/D Ratio |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit | cm³ | cm³ | cm³ | g | g | g | mm | mm | mm | L/D | L/D | L/D |

| JM88-MK6 | 135 | 183 | 237 | 123 | 166 | 216 | 31 | 36 | 41 | 24.4 | 21.0 | 18.4 |

| JM128-MK6 | 208 | 270 | 340 | 189 | 246 | 309 | 36 | 41 | 46 | 23.9 | 21.0 | 18.7 |

| JM168-MK6 | 303 | 382 | 488 | 276 | 347 | 444 | 41 | 46 | 52 | 23.6 | 21.0 | 18.6 |

| JM208-MK6 | 431 | 551 | 734 | 393 | 502 | 668 | 46 | 52 | 60 | 23.7 | 21.0 | 18.2 |

| JM258-MK6 | 636 | 847 | 1057 | 579 | 771 | 962 | 52 | 60 | 67 | 24.2 | 21.0 | 18.8 |

| JM328-MK6 | 947 | 1180 | 1479 | 861 | 1074 | 1346 | 60 | 67 | 75 | 23.5 | 21.0 | 18.8 |

| JM398-MK6 | 1321 | 1655 | 2027 | 1202 | 1506 | 1845 | 67 | 75 | 83 | 23.5 | 21.0 | 19.0 |

| JM468-MK6 | 1832 | 2244 | 2638 | 1667 | 2042 | 2401 | 75 | 83 | 90 | 23.2 | 21.0 | 19.4 |

| JM568-MK6 | 1832 | 2244 | 2638 | 1667 | 2042 | 2401 | 75 | 83 | 90 | 23.2 | 21.0 | 19.4 |

| JM668-MK6 | 2433 | 2861 | 3392 | 2214 | 2603 | 3087 | 83 | 90 | 98 | 23.9 | 22.0 | 20.2 |

Choose your options:

Chen Hsong Europe Headquarters are located in Germany, we have numerous machines and spare parts, as well as fully set up machines available for demonstration, testing and training.

All European customers and agents are supported from this location.

As the final day of PLASTPOL 2023 is nearing its end, we at Chen Hsong are thrilled to look back on a highly successful showcase

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

|

|

Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

Choose Your Region

The Chen Hsong Group has offices and distributors all around the globe.

Select your region from below or search our global list of distributors.