Upcoming Show: Plast Eurasia İstanbul in Istanbul

We are heading to Plast Eurasia next month with a focus on the “AI Era” of molding. It really comes down to smarter, more efficient

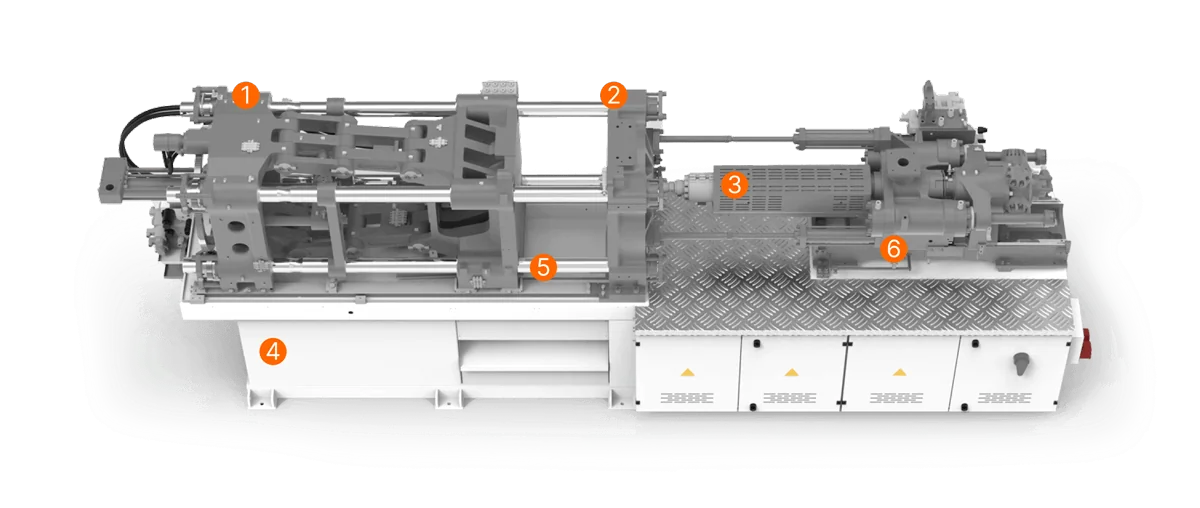

Proprietary Japanese mechanical design with highly-optimised motion profile; core components toggle produced on high-end machining centres to 0.01mm precision.

Proprietary Circular Platen design (patented) is a technological marvel perfected from years of detailed structural analysis, ensuring smooth

stress distribution throughout the platen for maximum part quality and mould protection.

Leveraging over 60 years of application expertise and field experience, professional screw designs are available for an amazingly wide range of applications demands and resins. There is always an optimised screw ready for your particular, unique processing needs.

Improved structural stability, reduced deformation and enhanced torsion resistance from thicker and stronger I-beams that make up the machine base, plus an optimised design created through high-end computer stress simulations of various loading conditions.

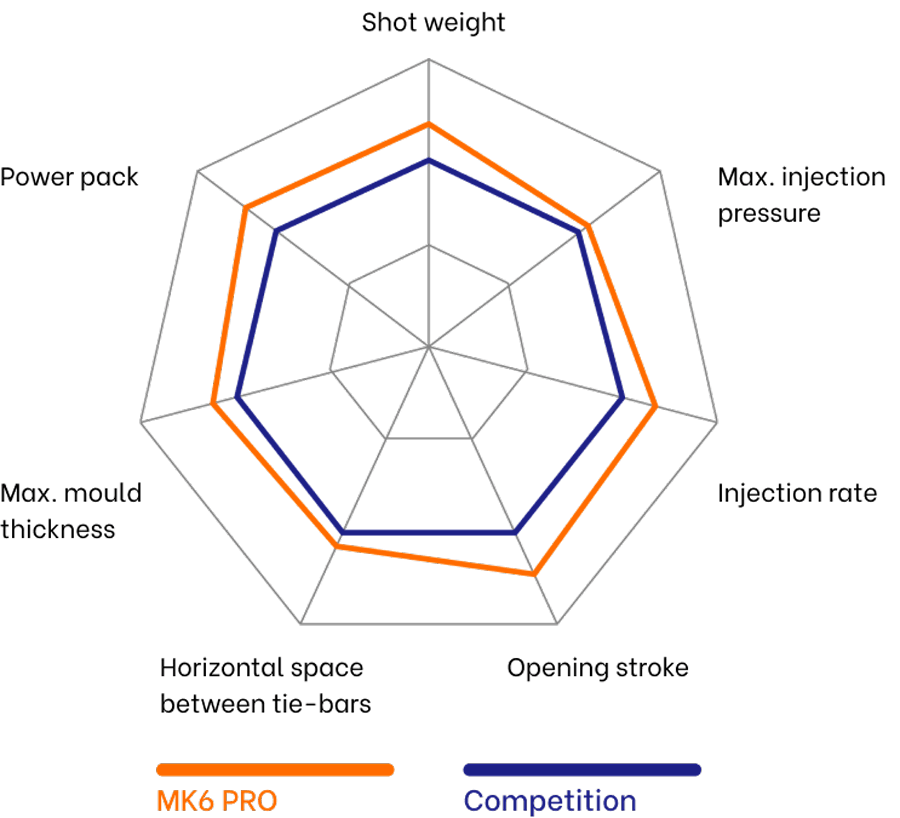

Highly precise control over speed, pressure andtemperature leads to easy processing of a wide range of resins, from PP, ABS to PC, PET, PMMA, PA and more exotic engineering plastics, where the MK6 PRO shows its professional colours.

Silky-smooth – low friction

Reliable – longer usage life

Stable – higher positional accuracy for higher yields

Fast – low friction enables higher speeds and better control

Precision – better control and accuracy leads to higher precision

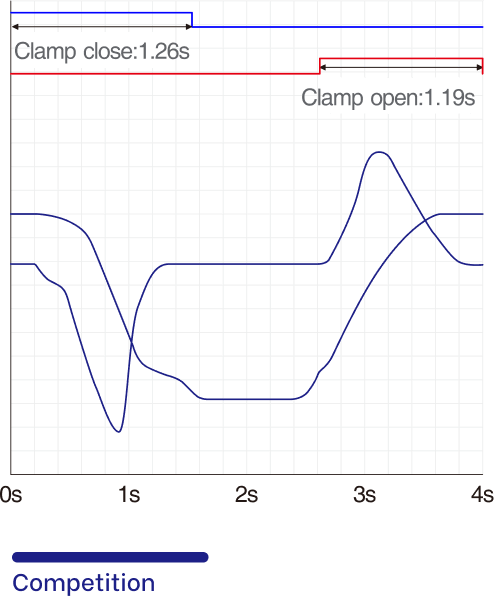

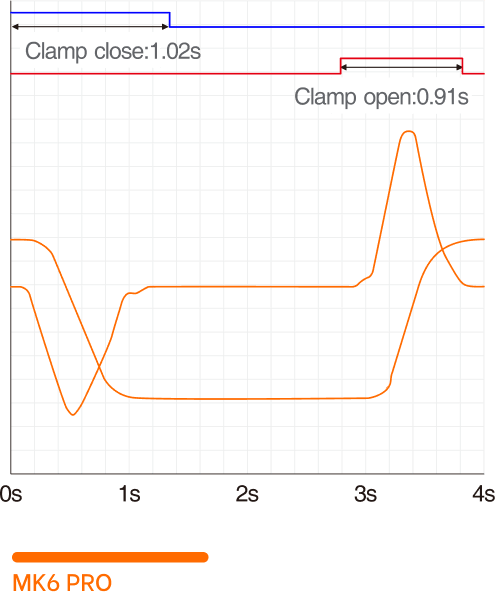

| Model | MK6 PRO 168T | Competition 168T |

|---|---|---|

| Clamp close (s) | 1.02 | 1.26 |

| Clamp open (s) | 0.19 | 1.19 |

| Cycle time (s) | 1.93 | 2.45 |

| Opening stroke (mm) | 300 | 300 |

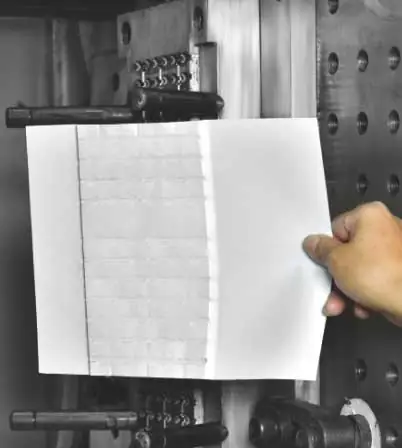

Large thin flat testing plate

Shot-weight: 122g

Cavities: 1

Resin: PE

Cycle time: 16.5s

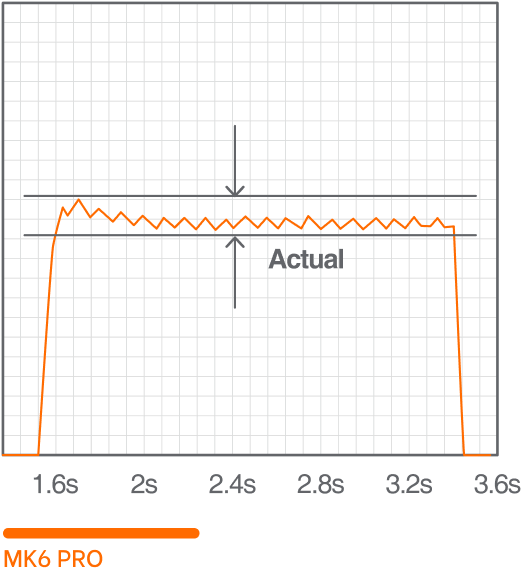

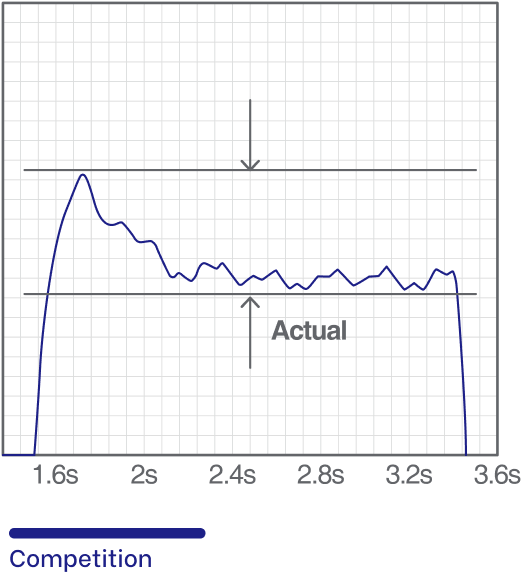

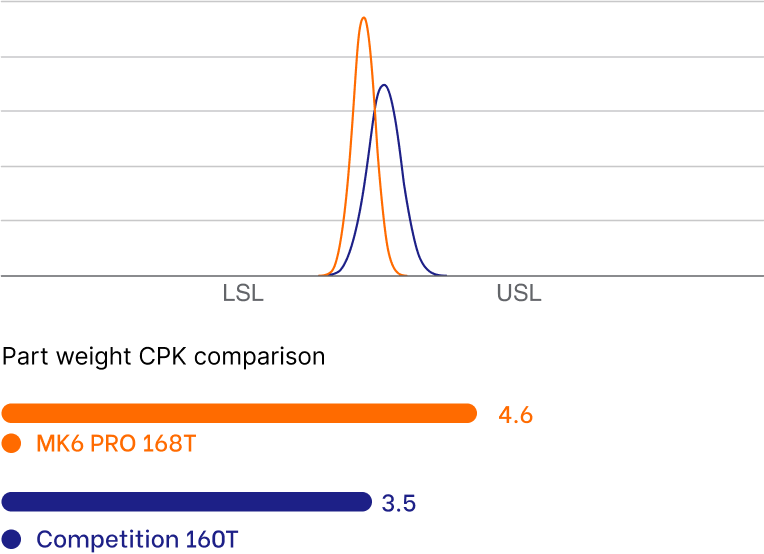

Better CPK

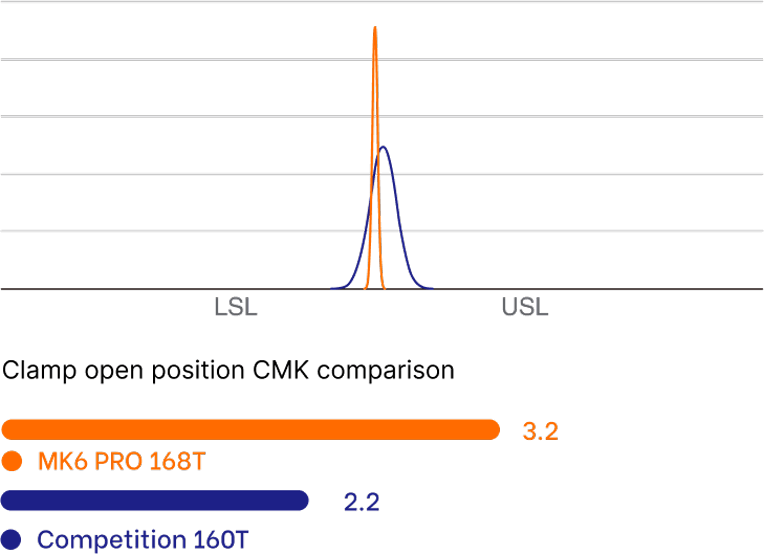

More accurate clamp-open precision

| Machine Model | Clamping Force (Max.) | Max. Clamp Stroke | Platen Size (H×V) | Tie Bars Distance | Max. Mould Thickness | Min. Mould Thickness | Max. Daylight | Ejector Force (Max.) | Ejector Stroke (Max.) | No. of Ejectors | Locating Ring Diameter |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit | kN | mm | mm | mm | mm | mm | mm | kN | mm | PCS | mm |

| JM88-MK6 PRO | 880 | 340 | 540×540 | 360 x 360 | 380 | 125 | 720 | 34 | 120 | 1 | 125 |

| JM128-MK6 PRO | 1280 | 380 | 600×600 | 410 x 410 | 450 | 150 | 830 | 42 | 120 | 1 | 125 |

| JM168-MK6 PRO | 1680 | 450 | 680×680 | 470 x 470 | 520 | 170 | 970 | 42 | 140 | 9 | 125 |

| JM208-MK6 PRO | 2080 | 510 | 760×760 | 530 x 530 | 550 | 180 | 1060 | 67 | 150 | 9 | 160 |

| JM258-MK6 PRO | 2580 | 560 | 840×840 | 580 x 580 | 580 | 190 | 1140 | 85 | 150 | 9 | 160 |

| JM328-MK6 PRO | 3280 | 660 | 970×970 | 680 x 680 | 680 | 225 | 1340 | 111 | 180 | 9 | 160 |

| JM398-MK6 PRO | 3980 | 720 | 1040×1040 | 730 x 730 | 730 | 250 | 1450 | 111 | 215 | 9 | 160 |

| JM468-MK6 PRO | 4680 | 820 | 1160×1160 | 830 x 830 | 730 | 250 | 1670 | 166 | 220 | 17 | 200 |

| JM568-MK6 PRO | 5680 | 870 | 1230×1230 | 860 x 860 | 850 | 300 | 1750 | 166 | 250 | 17 | 200 |

| JM668-MK6 PRO | 6680 | 920 | 1300×1300 | 920 x 920 | 880 | 350 | 1840 | 182 | 265 | 17 | 200 |

| Machine Model | Injection Capacity (Theoretical) | Injection Capacity (Theoretical) | Injection Capacity (Theoretical) | Injection Shot Weight (Max.) | Injection Shot Weight (Max.) | Injection Shot Weight (Max.) | Screw Diameter | Screw Diameter | Screw Diameter | Screw L/D | Screw L/D | Screw L/D |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit | cm³ | cm³ | cm³ | g | g | g | mm | mm | mm | L/D | L/D | L/D |

| JM88-MK6 PRO | 136 | 183 | 238 | 124 | 167 | 216 | 31 | 36 | 41 | 24.4 | 21.0 | 18.4 |

| JM128-MK6 PRO | 209 | 271 | 341 | 190 | 246 | 310 | 36 | 41 | 46 | 23.9 | 21.0 | 18.7 |

| JM168-MK6 PRO | 304 | 382 | 488 | 276 | 348 | 444 | 41 | 46 | 52 | 23.6 | 21.0 | 18.6 |

| JM208-MK6 PRO | 432 | 552 | 735 | 393 | 502 | 669 | 46 | 52 | 60 | 23.7 | 21.0 | 18.2 |

| JM258-MK6 PRO | 432 | 552 | 735 | 393 | 502 | 669 | 46 | 52 | 60 | 23.7 | 21.0 | 18.2 |

| JM328-MK6 PRO | 947 | 1181 | 1480 | 862 | 1075 | 1347 | 60 | 67 | 75 | 23.5 | 21.0 | 18.8 |

| JM398-MK6 PRO | 1322 | 1657 | 2029 | 1203 | 1508 | 1846 | 67 | 75 | 83 | 23.5 | 21.0 | 19.0 |

| JM468-MK6 PRO | 1833 | 2245 | 2640 | 1668 | 2043 | 2403 | 75 | 83 | 90 | 23.2 | 21.0 | 19.4 |

| JM568-MK6 PRO | 1833 | 2245 | 2640 | 1668 | 2043 | 2403 | 75 | 83 | 90 | 23.2 | 21.0 | 19.4 |

| JM668-MK6 PRO | 2300 | 2704 | 3306 | 2093 | 2406 | 2917 | 83 | 90 | 98 | 23.9 | 22.0 | 20.2 |

Chen Hsong Europe HQ in the Netherlands stocks machines and spare parts, and offers demos, testing & training. We support all European customers and agents. Contact us.

We are heading to Plast Eurasia next month with a focus on the “AI Era” of molding. It really comes down to smarter, more efficient

Choose Your Region

The Chen Hsong Group has offices and distributors all around the globe.

Select your region from below or search our global list of distributors.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |