Upcoming Show: Plast Eurasia İstanbul in Istanbul

We are heading to Plast Eurasia next month with a focus on the “AI Era” of molding. It really comes down to smarter, more efficient

From Steel to Smart: Chen Hsong’s Manufacturing 4.0 Vision

Amid global shifts toward heightened supply chain resilience, compelling sustainability mandates, and increasing market volatility, the manufacturing sector is navigating unprecedented demands for precision, efficiency, and adaptability.

This era, often dubbed Industry 4.0, isn’t just about automation; it’s about intelligent, interconnected systems.

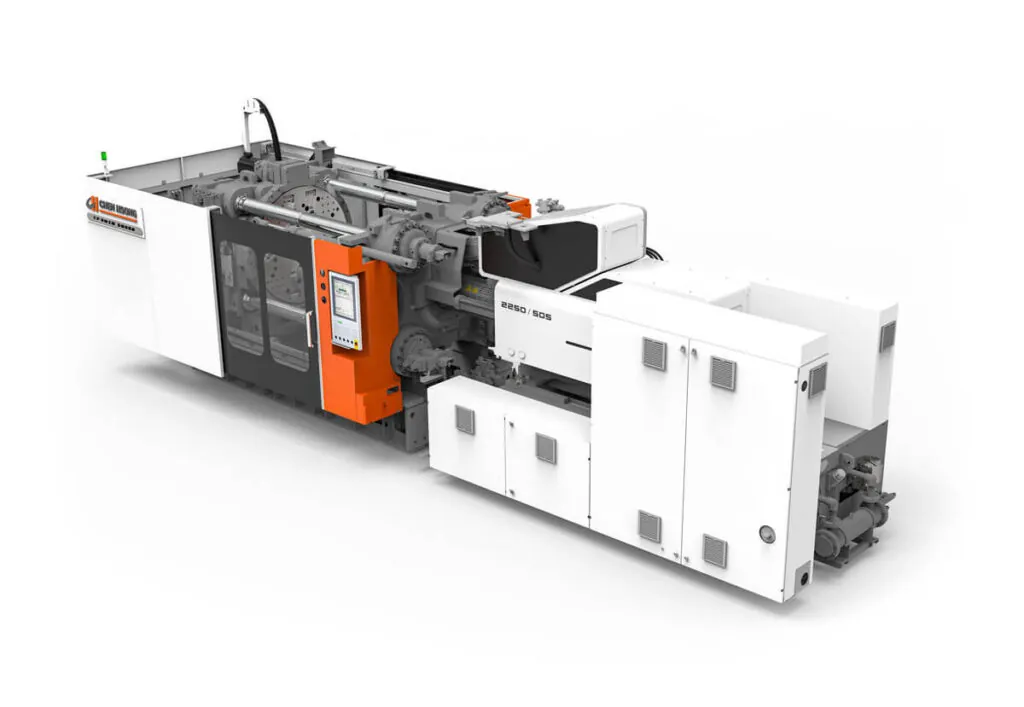

This machine integrates the advanced KEBA or B&R control system (upon request), ensuring proven reliability and precise operation.

Space-saving design enables simultaneous multi-material and multi-color molding for complex parts.

Boosts production efficiency 10%–30% by enabling simultaneous plasticising with mold open/close and ejection.

Flexible, expandable architecture minimises initial cost, maximises long-term investment value.

Space-saving design maximises workshop utilisation, fitting seamlessly into limited production areas.

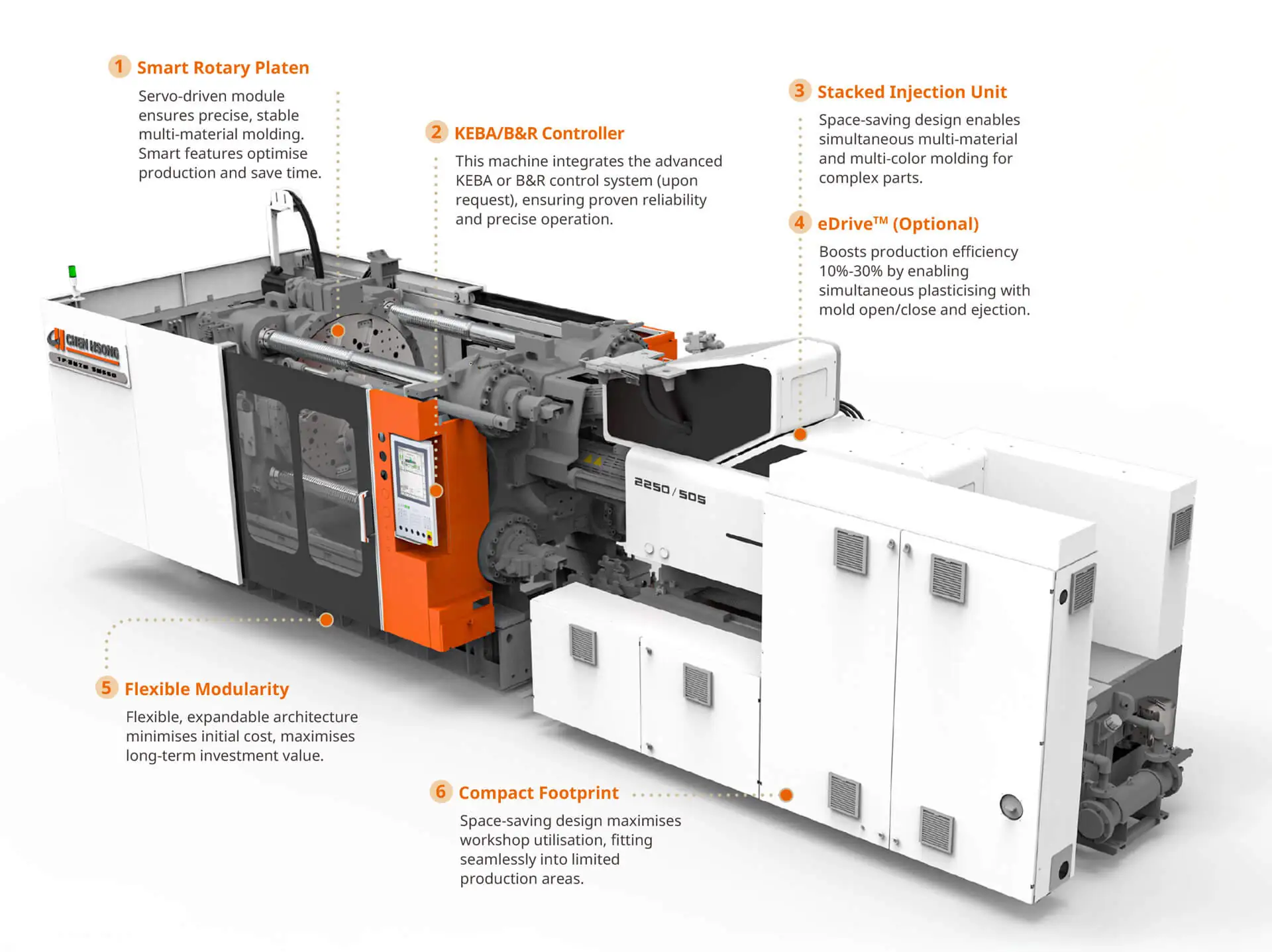

Engineered for ultimate versatility and repeatability, it precisely handles ultra-thin, intricate components and confidently molds large, demanding parts.

Experience hybrid’s electric responsiveness. Our servo system’s (<30ms) speed rivals top all-electric machines.

This machine integrates the advanced KEBA or B&R control system (upon request), ensuring proven reliability and precise operation.

Highly-optimised control algorithms work together with fine-tuned hardware designs to deliver perfect motion control.

Our Auto Stress Release system (ASRS) offers unmatched stability and stress distribution. Enjoy longer machine life, reduced repair costs, and zero downtime worries.

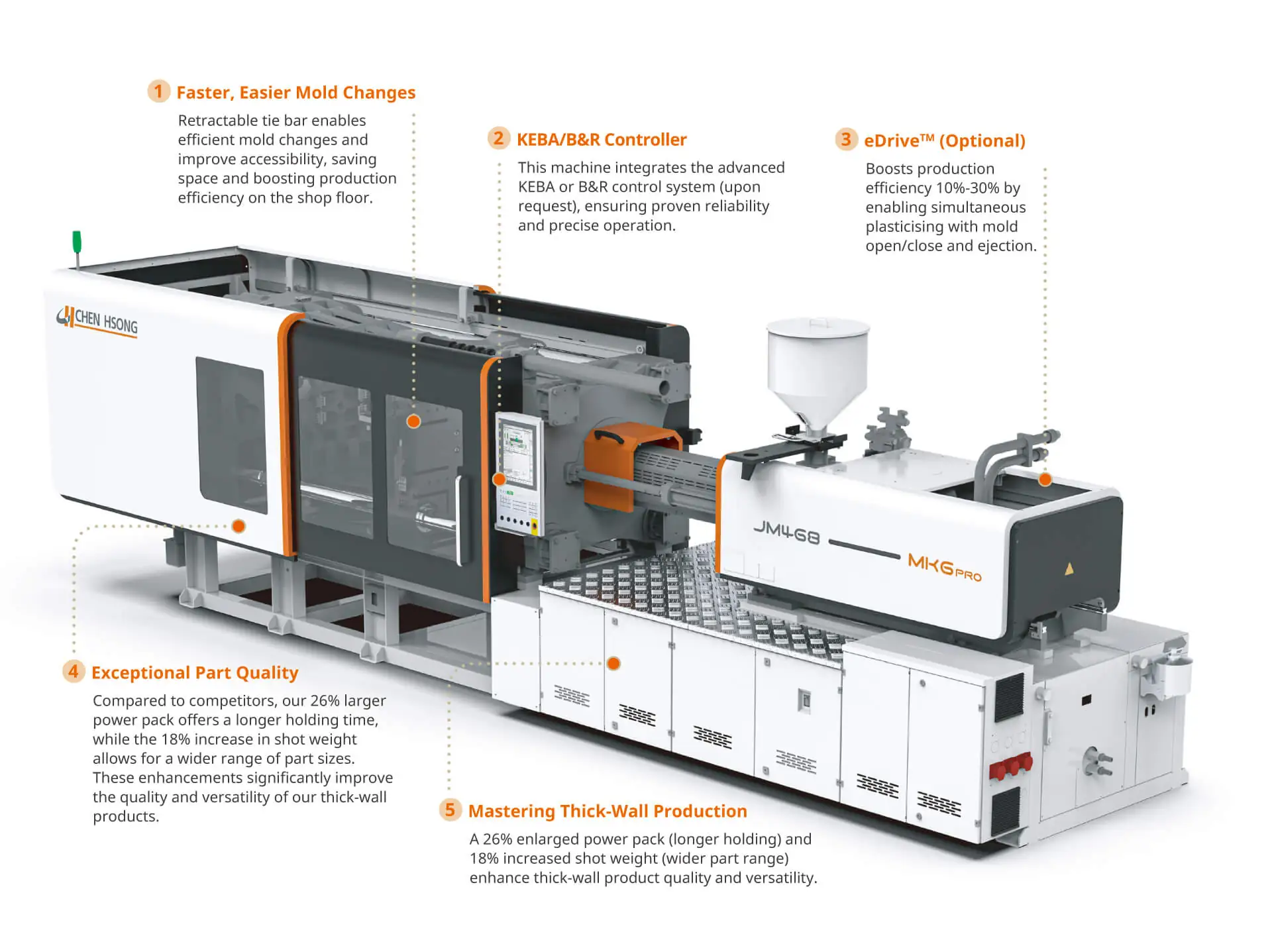

Retractable tie bar enables efficient mold changes and improves accessibility, saving space and boosting production efficiency on the shop floor.

This machine integrates the advanced KEBA or B&R control system (upon request), ensuring proven reliability and precise operation.

Boosts production efficiency 10%–30% by enabling simultaneous plasticising with mold open/close and ejection.

Compared to competitors, our 26% larger power pack offers a longer holding time, while the 18% increase in shot weight allows for a wider range of part sizes. These enhancements significantly improve the quality and versatility of our thick-wall products.

A 26% enlarged power pack (longer holding) and 18% increased shot weight (wider part range) enhance thick-wall product quality and versatility.

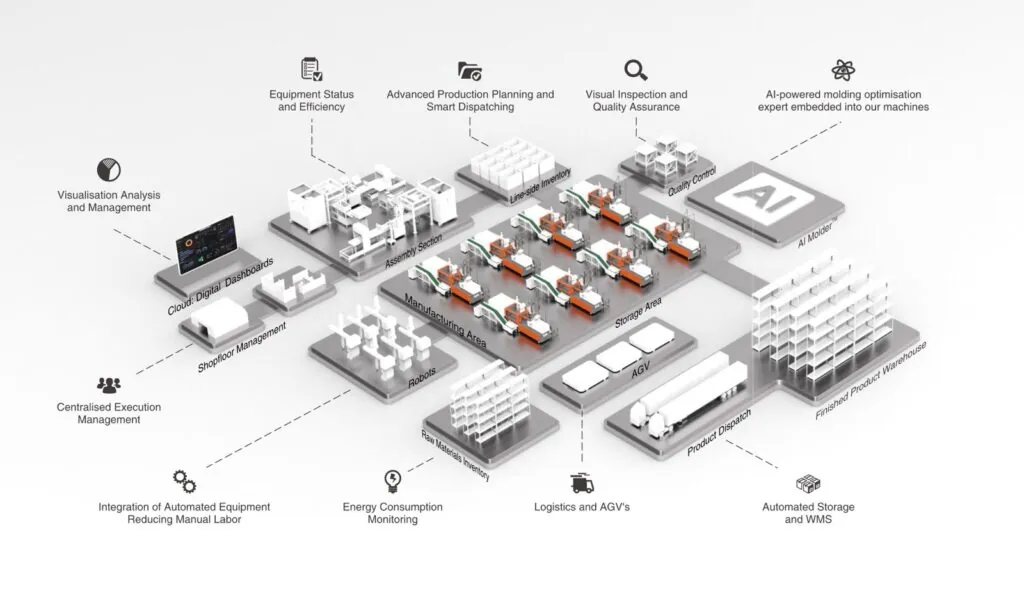

Think of this as the local nervous system of the factory. It’s built for operations on-site, giving production managers real-time visibility and control over machines, logistics, and quality.

While the Smart Factory manages operations on-site, iChen Cloud operates at the next level, linking multiple plants, systems, and regions into one coordinated platform.

Built for global enterprises, it delivers visibility, balance, and control across the entire organisation.

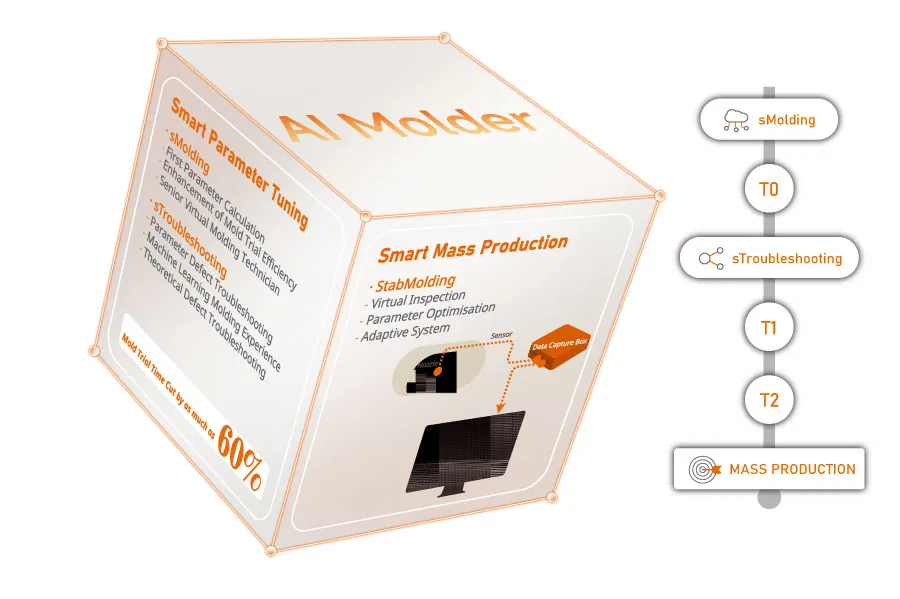

AI Molder is a machine-side assistant that shortens mold trials, stabilises production, and improves quality consistency.

sMolding

sTroubleshooting

StabMolding

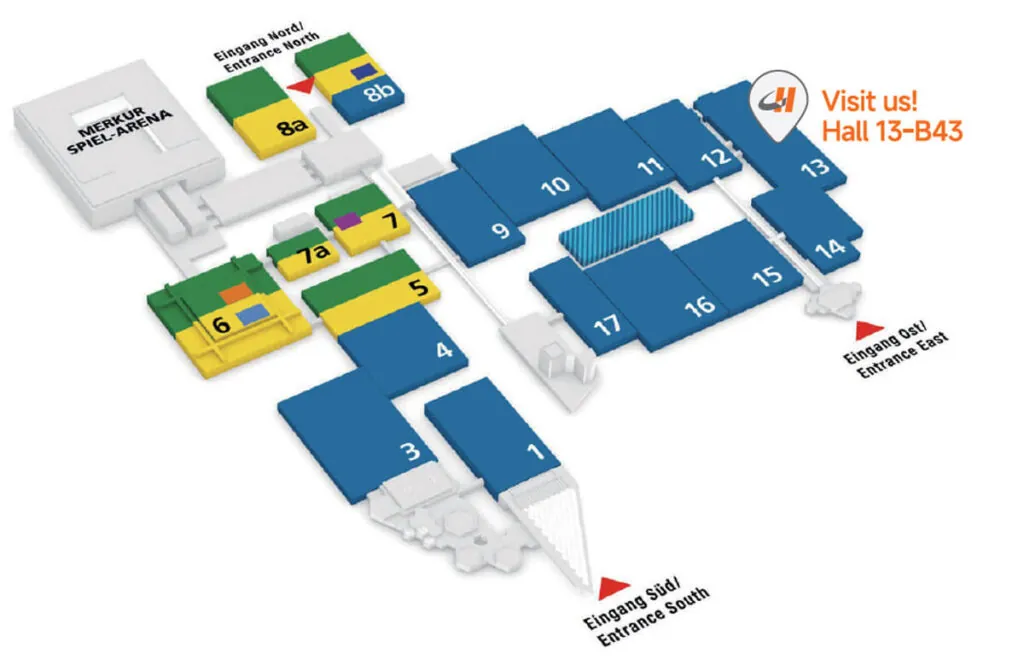

We’ll be at Hall 13, Booth B43. Use the form to schedule a meeting or ask us anything in advance.

Chen Hsong Europe HQ in the Netherlands stocks machines and spare parts, and offers demos, testing & training. We support all European customers and agents. Contact us.

We are heading to Plast Eurasia next month with a focus on the “AI Era” of molding. It really comes down to smarter, more efficient

Choose Your Region

The Chen Hsong Group has offices and distributors all around the globe.

Select your region from below or search our global list of distributors.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |